Self-adhesive stickers printed on self-adhesive foil. Cut along the outline or die-cut.

Self-adhesive stickers printed on self-adhesive foil. Cut along the outline or die-cut.

Self-adhesive stickers printed on paper, cut along the outline, delivered on sheets

Self-adhesive stickers printed on paper, cut along the outline, delivered on sheets

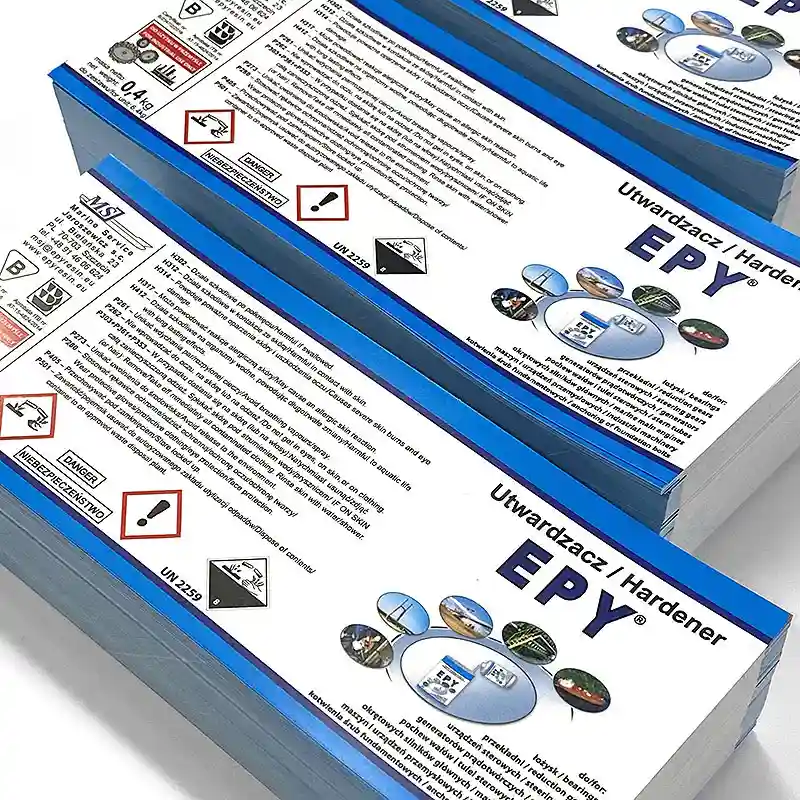

Self-adhesive labels printed on foil, rectangular, cut in stacks.

Self-adhesive labels printed on foil, rectangular, cut in stacks.

A sheet of stickers for children in the form of a folder. Each sticker has a different shape. Perforation in the middle enabling folding.

A sheet of stickers for children in the form of a folder. Each sticker has a different shape. Perforation in the middle enabling folding.

Self-adhesive labels for products. Stickers on sheets printed on paper.

Self-adhesive labels for products. Stickers on sheets printed on paper.

Round self-adhesive labels cut on sheets.

Round self-adhesive labels cut on sheets.

Self-adhesive pre-cut stickers delivered on sheets

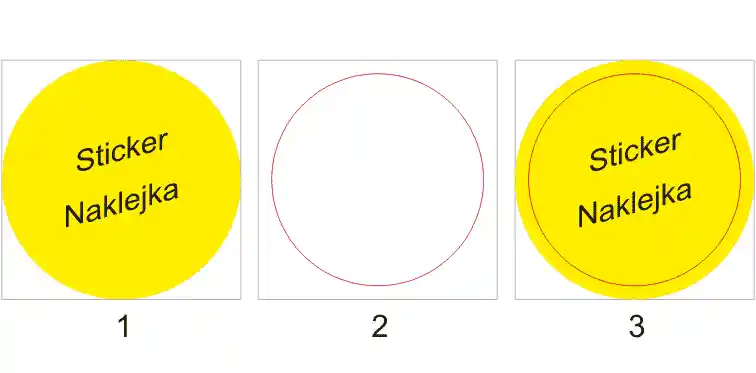

Self-adhesive pre-cut stickers delivered on sheetsThe picture shows exactly what the background bleed of the project is, we cut it off while cutting so that after peeling off the sticker from the transport paper, the print reaches every edge. The accuracy of graphics positioning relative to the cutting line is assumed to be < 1 mm. In most cases, repeatability is accurate to tenths of a mm

Sample PDF for printing a sticker

Sample PDF for printing a sticker1. PDF page one - design with background.

2. second page of PDF - cutting line.

3. the result of superimposing the first and second pages of the PDF

We produce stickers, self-adhesive labels on foil and paper in any shape and size.

We produce stickers, self-adhesive labels on foil and paper in any shape and size.

Printing stickers, labels, and self-adhesive tags.

✔printed ✔foil ✔paper ✔on sheets ✔cut ✔die-cut ✔kiss-cut ✔numbered ✔QR code ✔barcode

How to prepare a graphic design for printing a rectangular sticker or label?

The graphic design of the sticker should be prepared in a size consistent with the template of the ordered product. The template and its description are available on the left side of the product configurator. When designing, maintain margins of at least 3 mm, and if the background is not white, include a 2 mm bleed (format increased by 2 mm on each side). The print-ready design should be delivered in PDF/X-3 format (check the PDF export options in your application).

How to prepare a graphic design for printing a sticker or label in a shape other than a rectangle?

The graphic design of the sticker should be prepared in a size consistent with the ordered product. The PDF document should be prepared in such a way that the first page contains the sticker design and the second page contains the cut contour of the finished sticker. The positioning of the cutting contour on the second page should correspond to the position of the sticker on the first page of the PDF document. The print-ready sticker design should be delivered in PDF/X-3 format (check the PDF export options in your application).

What to do if you don't have your own design for printing a sticker or label?

You can order the design from our printing house. To do this, prepare a clear description and high-quality materials that will allow us to efficiently execute it. The design completion time for a sticker or label is determined individually and is not included in the order fulfillment time specified in the product configurator on the printing house's website.

What substrates are used for printing stickers/labels?

- Matte self-adhesive paper (with or without a cut substrate)

- Glossy self-adhesive paper (with or without a cut substrate)

- Uncoated self-adhesive paper (with or without a cut substrate)

- Self-adhesive foil

The materials used for printing stickers and self-adhesive labels have varying adhesion to the substrate and durability under prevailing conditions.

Our printing house offers foil stickers/labels with permanent and non-permanent adhesive (allowing the sticker to be removed without leaving adhesive residue on the surface).

How are self-adhesive stickers/labels printed?

Printing is done on sheets in full color with the Euroscale CMYK palette at a high resolution of 2400 DPI, which allows reproducing photos, text, and graphic symbols in the finest details. Prints can be ordered from as little as one piece, ensuring that after approving the sample sticker, the entire series of target sticker/label production will look the same. This helps to avoid unwanted surprises during delivery.

What is the durability of printed stickers and labels?

The print on the foil stickers produced by us is characterized by very high resistance to weather conditions, abrasion, and contact with chemicals, allowing for wide use of the printed labels and stickers from our printing house.

✅ Chemical resistance test

Tests conducted in our printing house confirmed that the labels and stickers we produce on self-adhesive foil do not get damaged after multiple wipes with a cloth soaked in alcohol, gasoline, or denatured alcohol, which significantly differentiates them from most digitally printed stickers offered in the printing market.

✅ Scratch resistance test

Another test conducted on our stickers is scratch resistance. We scratched the print on the sticker with the tip of a small screwdriver with moderate force that does not tear or wrinkle the foil. As a result of the test, clear indentations appeared in the foil, and the print retained its continuity in them.

✅ Weather resistance test

Stickers were applied to the metal gate doors facing south, where there is significant sunlight. After a year of exposure to weather conditions, the stickers showed no noticeable color changes, and the foil did not peel off the substrate.

What are the uses of self-adhesive stickers and labels?

The stickers and labels printed in our printing house, thanks to their high quality and durability, are commonly used as: packaging labels, control panel stickers, device stickers, nameplates, homologation stickers on fire extinguishers, bottle labels, honey jar labels, advertising stickers, cleaning product labels, food product labels, product stickers, coloring stickers for children, and many more.

How are printed self-adhesive stickers and labels delivered?

- Rectangular stickers (cut) are delivered in stacks (each piece separately)

- Stickers of any shape (die-cut) are delivered in stacks (each piece separately)

- Stickers of any shape (kiss-cut) are delivered on A4 or A3 sheets (multiple pieces on one sheet)

Stickers delivered in stacks allow for individual distribution. Peeling off the sticker delivered in a stack from the backing paper takes significantly more time than peeling a sticker delivered on a sheet, so they are not suitable for serial production of any products. Stickers in stacks are delivered on a cut backing for easier separation from the transport substrate. Stickers in stacks cannot be smaller than a business card size, and the margins must be > 5 mm. Miniature, precisely cut stickers with a small margin are only delivered on sheets.

Stickers delivered on sheets are very easy and quick to peel off from the substrate, saving a lot of time when applying serially to products. Stickers on sheets can have any shape and miniature size, e.g., 10x10 mm, while maintaining precise cutting with margins > 1 mm. Stickers on sheets have spacing between them that is individually determined based on technical capabilities. Typically, the spacing between stickers ranges from 0 to 5 mm. Stickers delivered on sheets are easy and safe to transport, pack, and store without risking edge damage.

What other types of stickers do we produce in our printing house?

Our printing house also offers other types of self-adhesive products:

Warranty seals - stickers printed on security foil that crumbles when attempting to peel off. These types of stickers can be found in the warranty seals category.

Stickers with variable text (personalized, numbered, coded, marked) – according to needs, each label or sticker can be differently marked. Sequential numbering or alphanumeric coding, barcode, QR code can be printed from a provided XLSX file. If needed, contact us to determine the technical details.

What is the delivery time and cost of printed labels and stickers?

The product configurator available on the printing house's website instantly calculates the delivery time and product price. Two delivery times are available: standard or express. We invite you to contact the printing house to negotiate an individual delivery time for sticker printing if necessary.

If you have additional questions

about the stickers, labels, or seals printed by our company, feel free to contact us. Sticker Printing Designer is waiting for your questions from 8 AM to 8 PM. We invite you to contact us, we will be happy to answer all your questions.