Visible security effect when using a self-adhesive seal

Visible security effect when using a self-adhesive seal

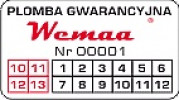

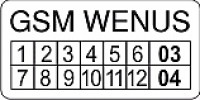

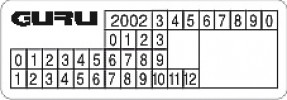

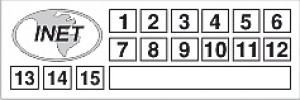

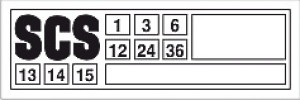

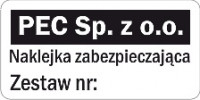

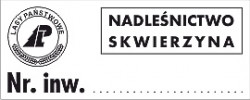

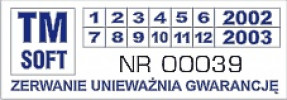

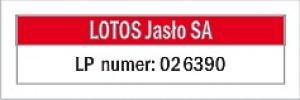

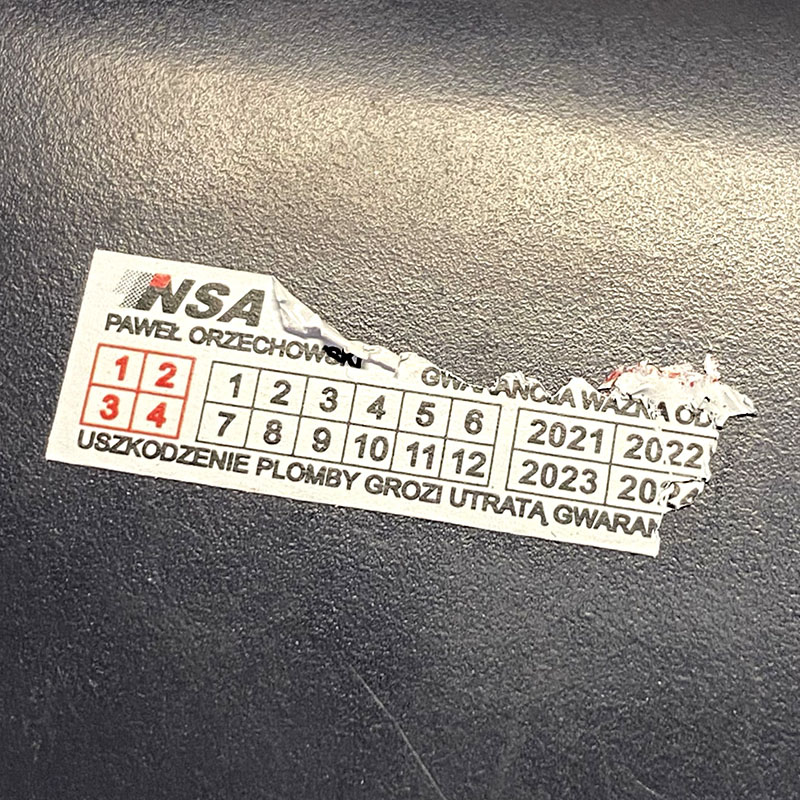

Examples of applications of self-adhesive security seals

Examples of applications of self-adhesive security seals

The self-adhesive guarantee seals can be easily removed from the sheet on which they are delivered.

The self-adhesive guarantee seals can be easily removed from the sheet on which they are delivered.

Self-adhesive guarantee seal after an attempt to peel off

Self-adhesive guarantee seal after an attempt to peel off

We deliver sticker type self-adhesive seals on A4 sheets

We deliver sticker type self-adhesive seals on A4 sheets

Sample PDF for printing the sticker

Sample PDF for printing the stickerP1. first page PDF - design with background.

P2. second page PDF - cutting line.

Security stickers, labels, self-adhesive warranty seals,

Indispensable in modern business

Self-adhesive security stickers, also known as warranty seals, play a crucial role in many industries by ensuring the security and integrity of products and documents. Their versatility and effectiveness make them an indispensable tool in preventing unauthorized opening, use, or even replacement of equipment.

Industries using self-adhesive security seals

Electronics: In the electronics industry, warranty seals are commonly used to secure computers, mobile phones, and other electronic devices. Their presence ensures that devices have not been opened or modified by unauthorized persons, which is key to maintaining warranties and user safety.

Casinos and Hypermarkets: In places such as casinos and hypermarkets, security seals play a vital role in protecting equipment and preventing theft and tampering. These seals are also used to secure meters and tickets, preventing counterfeiting and misuse.

Facility Equipment and Fixed Assets: Warranty seals are also used to protect facility equipment and fixed assets. They allow for easy tracking and identification of equipment and prevent unauthorized use or theft.

Additional Applications

Self-adhesive seals can also serve to hinder access to information. Sealed text or descriptions require laborious scraping, deterring potential intruders from attempting to read or modify secured data.

Benefits of using warranty seals

The main advantage of warranty seals is avoiding unnecessary inconveniences and expenses related to unauthorized access to equipment or information. The use of seals allows for quick and easy detection of tampering attempts, significantly enhancing security levels.

Warranty seals can be customized to meet individual user needs, offering a variety of shapes and sizes. This allows for easy adaptation to specific requirements and applications, increasing their effectiveness and utility.

Summary

Self-adhesive warranty seals are an indispensable tool for securing products and information in many industries. Their versatility, effectiveness, and ability to be customized to individual needs make them a valuable element in modern business, helping to protect against unauthorized access and tampering.

What substrates are used for printing warranty labels?

Self-adhesive warranty seals are printed on special foil that, once applied and dried, cannot be removed in one piece. Any attempt to remove the seal results in the foil crumbling, preventing reattachment without visible traces. The foil we use does not conduct electricity, making it suitable for direct application on electronic circuit boards.

How are warranty seals printed?

Printing is done in black or color at a high resolution of 2400 DPI, allowing for the reproduction of photos, texts, and graphic symbols in the finest detail. Printing is done in sheets, and the finished seals are delivered on A4+ sheets. The foil surface is pre-cut for easy removal of individual stickers.

What size and shape can a warranty label have?

The configurator on the print shop's website allows for the ordering of warranty seals in any size and shape. Labels can be rectangular with straight or rounded corners, or any other shape according to the customer's needs.

What are the options for unique marking of warranty labels?

Each security sticker/seal can have a different code for inventory purposes. Numbering can be sequential, e.g., from 0001 to 1000, digital, or in the form of a barcode. Self-adhesive seals can also be marked in a unique way, e.g., alphanumeric. In this case, it is necessary to provide an XLS file containing the individual codes in the first column, row by row.

What is the lead time for printing self-adhesive warranty seals?

The product configurator available on the print shop's website quickly calculates the lead time and product price. Two lead times are available: standard or express. Please contact the print shop to negotiate an individual lead time for printing labels if needed.

How to prepare a graphic design for printing a rectangular warranty seal?

The graphic design of the sticker should be prepared in the size corresponding to the ordered product template. The template and its description are available on the left side of the product configurator. When designing, maintain margins of at least 1 mm, and for non-white backgrounds, a 2 mm bleed (enlarged by 2 mm on each side). The ready-to-print design should be delivered in PDF X-3 format (check the PDF export options in your application).

How to prepare a graphic design for printing warranty seals in shapes other than rectangular?

The design should be prepared in the size corresponding to the ordered product. The PDF document should be prepared so that the first page contains the seal design and the second page contains the contour of the seal's shape. The position of the cutting contour on the second page should correspond to the position of the seal on the first page of the PDF document. The ready-to-print warranty seal design should be delivered in PDF/X-3 format (check the PDF export options in your application).

Warranty seal design project?

You can order the design of the seal at our print shop or choose from ready-made templates available in the product configurator. For this purpose, prepare a clear description and materials that will allow us to complete it efficiently. The label design completion time is determined individually and is not included in the lead time indicated in the product configurator on the print shop's website.

If you have additional questions

About the warranty stickers printed by our company, please contact us. Plomb Designer Print Shop is available for your questions from 8 am to 8 pm. Feel free to contact us; we are happy to answer all your questions.